Expert Tips for Efficient Split System Installation

A Comprehensive Guide to Split System Installation

Split system installation is an essential process for ensuring effective and efficient heating and cooling in residential and commercial spaces. By allowing for centralized temperature control without the need for extensive ductwork, split systems have become increasingly popular. This article will delve into the steps required for a successful split system installation, types of systems available, common challenges faced during installation, maintenance tips, and energy efficiency considerations.

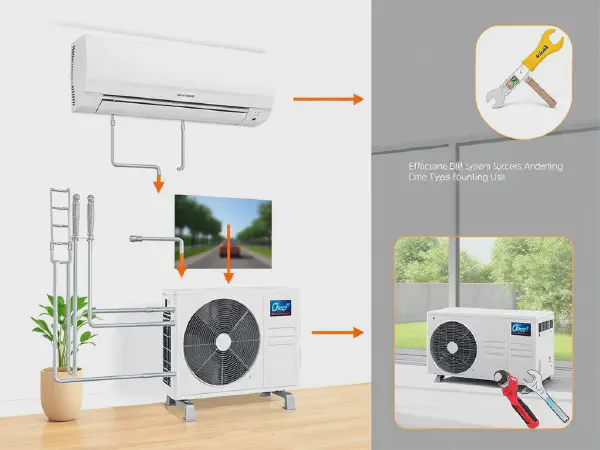

Understanding the nuances of split system installation is crucial for both homeowners and HVAC professionals. Proper installation not only maximizes system performance but also prolongs the life of the unit. A split system consists of an outdoor unit, which houses the compressor and condenser, and one or more indoor units that distribute heated or cooled air throughout the space. This article will explore the various types of split systems and the best practices for installation.

The importance of a well-executed split system installation cannot be overstated. Poorly installed systems can lead to inefficiencies, higher energy bills, and even the premature failure of the equipment. Therefore, having a comprehensive understanding of the installation process, potential challenges, and maintenance requirements is vital. By following the guidelines outlined in this article, you can ensure that your split system operates effectively for many years to come.

For optimal performance and energy efficiency, consider how dp refrigeration technology can enhance your cooling systems.

Before diving into the specifics of split system installation, it's important to consider the different options available on the market. Each type of split system comes with its unique features and advantages, making it essential to choose one that best suits your needs. In the following sections, we will take a closer look at various split system types and the installation process, along with common challenges and maintenance tips to enhance longevity and efficiency.

In conclusion, split system installation can be an intricate process that requires careful planning and execution. With a clear understanding of the different system types, the installation steps involved, and proactive maintenance measures, homeowners can create a comfortable and energy-efficient environment. By keeping these considerations in mind, you can make informed decisions that will benefit both your comfort and your wallet.

Understanding the cost to run ducted air conditioning is essential for budgeting and making informed choices for your home.

Types of Split Systems

Ductless split systems are a type of HVAC system that allows for individual temperature control in different rooms without the need for ductwork. This makes them an ideal choice for renovations, additions, or historical homes, where installing ducts may not be possible or practical. They come in various styles, including wall-mounted, ceiling-mounted, and floor-mounted models.

Mini-split systems are smaller versions of ductless systems that are designed to provide efficient heating and cooling for single rooms or small spaces. They consist of an outdoor condenser unit and one or more indoor air-handlers. Mini-splits offer flexibility in installation and can be used to increase comfort in areas that lack existing ductwork.

Multi-split systems operate similarly to mini-splits but allow for multiple indoor units to connect to one outdoor unit. This option is perfect for larger homes or buildings, as it offers individual climate control for different areas while conserving outdoor space. Additionally, multi-splits are energy efficient and can reduce the costs associated with running multiple systems.

Central split systems typically involve the use of ductwork to distribute conditioned air throughout the home. These systems consist of an outdoor condenser and an indoor air handler. While central systems generally provide consistent heating and cooling across larger spaces, they require more installation time and cost due to ductwork.

Portable split systems are a flexible option for spaces that lack permanent heating and cooling solutions. These units can be moved from room to room as needed, making them an excellent temporary solution for specific situations. However, they may not be as efficient or effective as installed systems and usually require venting through a window.

Installation Process

Preparation and planning are crucial steps in the installation process to determine the best location for the outdoor and indoor units, ensuring optimal performance and accessibility for maintenance. It is essential to check building codes and regulations, as these can significantly impact the installation process.

Choosing the right location for both the indoor and outdoor units is essential for the system’s efficiency. The outdoor unit should be placed in a well-ventilated area, away from any obstructions, while the indoor unit should be located in a space that allows for optimal air circulation. Consider the layout of the rooms and the distances between units when finalizing locations.

Mounting the indoor unit involves securing it to the wall or ceiling, depending on the chosen model. This requires drilling holes for mounting brackets and ensuring any necessary drainage lines are properly positioned. Take the time to accurately level the indoor unit to prevent drainage issues down the line.

Connecting refrigerant lines is a technical part of the installation process that requires precise measurements and careful handling. The lines must be insulated to prevent energy loss, and proper flaring techniques should be employed to prevent refrigerant leaks. It is essential to check the lines for any bends that could restrict airflow.

Testing the installation involves checking for refrigerant leaks, ensuring that the system turns on and off correctly, and verifying that each indoor unit cools or heats efficiently. Make sure to check all electrical connections and settings to ensure everything operates as intended before completing the installation.

Common Challenges

Leaking refrigerant is one of the most commonly encountered issues during split system installation and can lead to significant efficiency losses. It’s essential to regularly inspect the connections for signs of wear or damage and promptly address any leaks to maintain system performance.

Improper sizing of units can lead to inefficiencies and discomfort in your living space. Selecting a system that is too large or too small can result in frequent cycling, increased energy costs, and inadequate temperature control. Consulting with an HVAC professional can help ensure the right size system is chosen.

Electrical issues are another common challenge during installation. Ensure that all wires are properly connected and that the unit is connected to a suitable power source. It’s crucial to follow all safety precautions and codes to avoid electrical failures and potential hazards.

Drainage problems can occur if the indoor units are not installed correctly or if the drainage lines are clogged. Be sure to follow manufacturer guidelines for proper drainage installation, and conduct regular inspections to ensure that water can flow freely and without obstruction.

Noise and vibration concerns may arise if the outdoor unit is not securely mounted or if it’s placed too close to walls or other structures. Installing vibration dampeners and ensuring proper spacing can help reduce noise levels and ensure that the unit operates quietly and efficiently.

Maintenance Tips

Regular filter cleaning is essential for maintaining indoor air quality and system efficiency. Filters should be cleaned or replaced every month or as needed, depending on usage and environmental conditions. This helps prevent restricted airflow and ensures that the system operates effectively.

Checking refrigerant levels is vital for optimal performance. If the levels are low, the system may struggle to cool or heat properly. Regular inspections and maintenance by an HVAC professional can help identify and resolve refrigerant issues before they escalate.

Inspecting electrical connections is a key aspect of split system maintenance. Loose or corroded connections can lead to system failures, so it’s important to conduct routine checks and tighten connections as necessary to avoid outages.

Cleaning external units is an important maintenance tip to ensure proper airflow and performance. Remove any debris, leaves, or dirt that may have accumulated around the unit, and use a soft brush or vacuum to clean the fins and coils.

Scheduling professional servicing is crucial for the longevity of your split system. An HVAC technician can conduct a thorough inspection, clean the system, and address any issues that may not be apparent to the homeowner, ensuring that the system continues to operate efficiently and effectively.

Energy Efficiency

Choosing energy-efficient models is the first step toward achieving optimal energy performance. Look for units with high energy efficiency ratings, as these models typically consume less electricity while delivering the same level of comfort.

Understanding SEER ratings is essential when evaluating the efficiency of split systems. The Seasonal Energy Efficiency Ratio (SEER) measures the efficiency of air conditioning systems; higher ratings indicate better efficiency and lower operating costs. Selecting a system with a high SEER rating can lead to significant energy savings over time.

Optimizing thermostat settings can further enhance energy efficiency. Setting the thermostat to a comfortable yet energy-saving temperature can reduce energy consumption and lower utility bills. Consider using programmable thermostats to automate temperature adjustments based on occupancy.

Insulating ductwork is key for ensuring that conditioned air reaches its destination without significant losses. If using a central split system, ensure that ducts are properly insulated and sealed to maximize energy efficiency.

Benefits of inverter technology in split systems should not be overlooked. Inverter-driven compressors adjust their speed based on the cooling or heating demand, providing consistent temperature control while consuming less energy than traditional systems. This leads to reduced energy costs and improved comfort.